In the unseen world of steel, countless bolts bear immense pressure. From the smallest wind turbine towers to the largest rocket launch pads, the tightness of every single bolt directly affects the safety and stability of the entire structure.

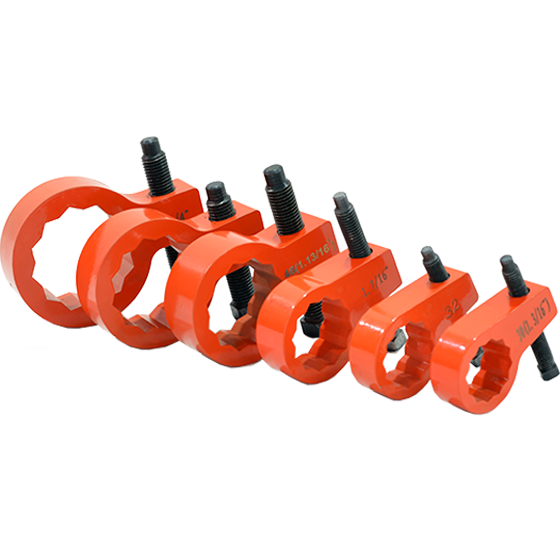

I. What is a Hydraulic Torque Wrench?

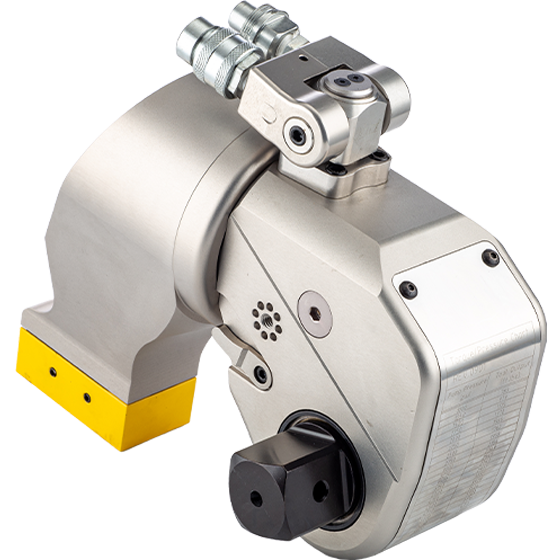

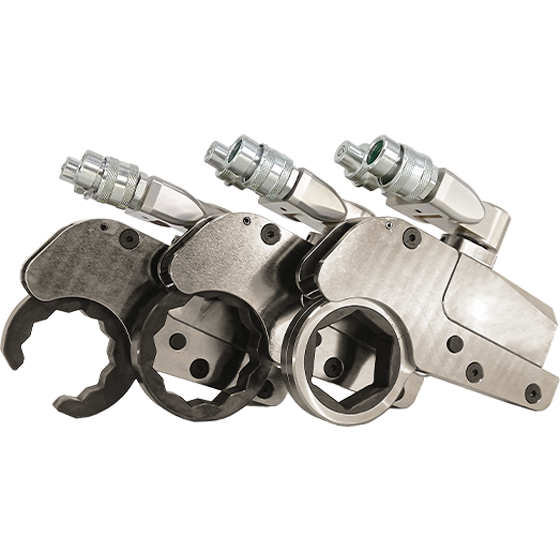

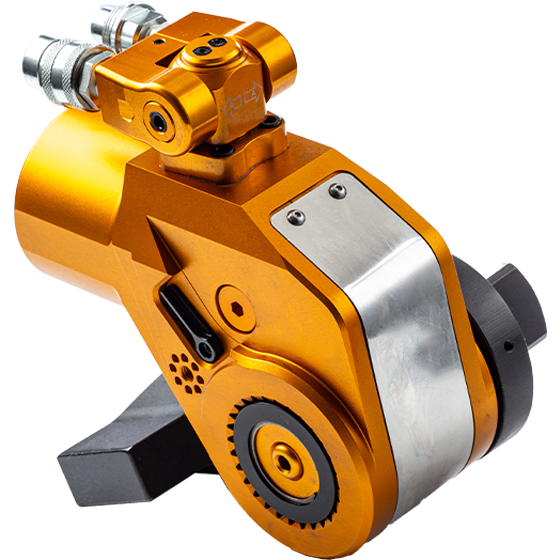

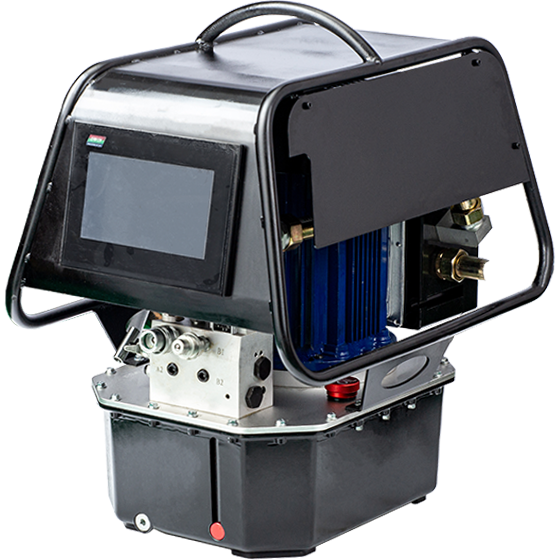

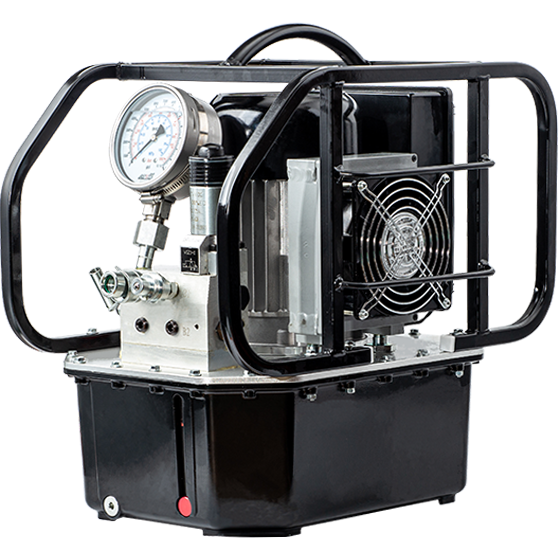

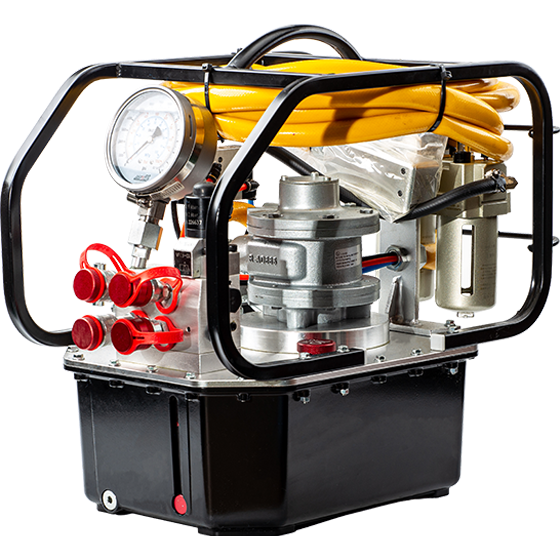

Simply put, a hydraulic torque wrench is a tool that generates immense, precise torque through a hydraulic system to tighten or loosen large-diameter bolts. Compared to traditional manual or pneumatic wrenches, it offers advantages such as high output force, high precision, high efficiency, and low reaction force.

II. Core Application Scenario

1. Wind Power Sector

Tall wind turbines rely on high-strength bolts to connect massive components such as towers, nacelles, and blades. At heights exceeding 100 meters, these bolts must maintain precise and uniform preload under complex conditions like strong winds and vibrations.

Application Scenarios: Tower flange connections, nacelle mounting, blade bearing fastening, etc.

Value: Prevents bolt loosening due to vibration or overload failure, ensuring stable operation throughout the turbine's design life and avoiding catastrophic incidents.

2. Petrochemicals and Heavy Machinery

In refineries and chemical plants, the integrity of massive reaction towers, pressure vessels, and pipeline flanges forms the first line of defense for safety. These facilities typically operate under extreme conditions of high temperature, high pressure, and flammable/explosive environments.

Applications: Reactor end cap sealing, large flange connections, compressor/turbine installations, etc.

Value: Ensures uniform force distribution across flange surfaces to achieve perfect sealing, fundamentally preventing safety incidents and environmental pollution.

3. Power Construction

Whether it's steam turbines in thermal power plants, hydro turbines in hydroelectric stations, or transmission towers and substation equipment in power transmission and transformation, all must withstand immense mechanical stress and electrodynamic forces.

Applications: Securing turbine/generator end caps, transformer installation, high-voltage switchgear connections, and reinforcing transmission tower joints.

Value: Ensures stable operation of core power equipment by preventing vibration and wear caused by bolt loosening; guarantees reliable connections at power transmission nodes to maintain grid stability.

4. Bridges and Steel Structure

Modern large-scale bridges, stadiums, and skyscrapers all utilize steel structures, with components connected by high-strength bolt assemblies. The quality of these bolt assemblies' tightening directly determines the strength and stability of the entire structure.

Applications: Steel box girder bridge segment splicing, main building steel structure node fastening, large venue truss installation.

Value: Enables thousands of steel components to work in concert, collectively resisting external forces like wind loads and earthquakes, ensuring the safety of century-long engineering projects.

III. Why Is It Indispensable? The Four Major Advantages of Hydraulic Torque Wrench.

In these high-end applications, customers choose hydraulic torque wrenches precisely for their irreplaceable value:

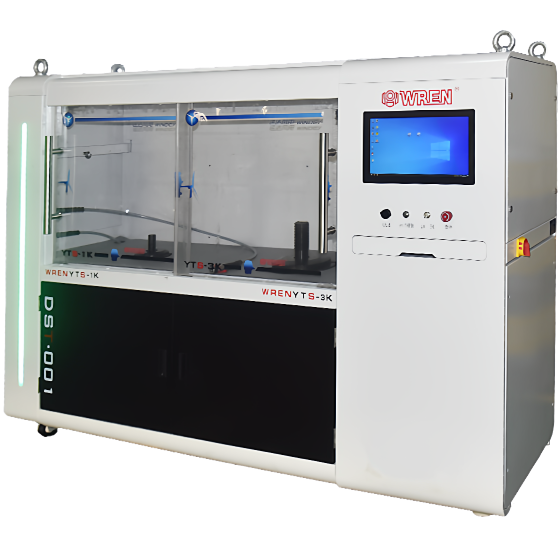

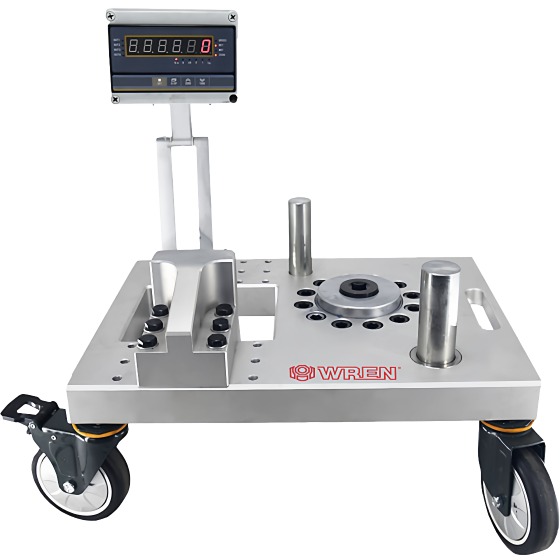

1. Precision Control: Torque accuracy reaches ±3%, far surpassing other tools to prevent under-tightening or over-tightening.

2. High Efficiency & Labor Savings: Hydraulic drive completes high-strength bolt tightening in minutes, significantly boosting productivity while reducing worker fatigue.

3. Safety and Reliability: Features a reaction arm design that effectively counteracts torque-induced forces, safeguarding operators while offering strong spatial adaptability for operation in confined spaces.

4. High Consistency: Compatible with synchronized hydraulic systems, enabling simultaneous use of multiple wrenches to ensure uniform torque distribution across all bolts on a single flange—a capability unattainable with manual tools.

In the industrial world, the greatest cost is often “uncertainty.” Hydraulic torque wrenches are precisely the key that transforms ‘uncertainty’ into “absolute reliability.”