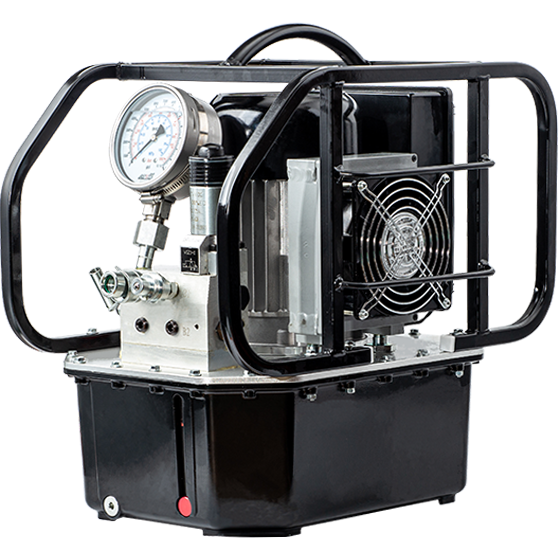

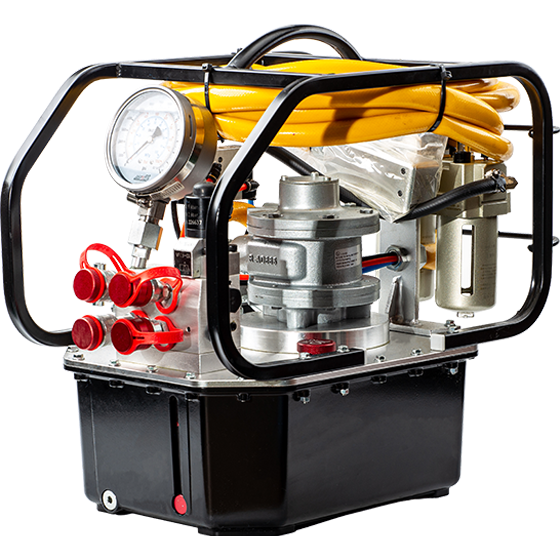

Now the demand for hydraulic wrenches is growing, the use of hydraulic wrenches can be seen in many industries, and there are many hydraulic wrench manufacturers for you to choose from. Under normal circumstances, hydraulic wrenches factory torque accuracy are nominal ± 3%, but there are some small workshop type manufacturers, the production of hydraulic wrenches is difficult to reach this value, in order to use the safety of the scene, the customer will need to carry out hydraulic wrench torque calibration.

The calibration period of the hydraulic wrench is mainly related to the frequency of use and the working environment. High frequency of use of three months calibration, less use of a year calibration; poor working conditions (high temperature, dusty), three months calibration. In general, it is enough to calibrate once in the second half of the year, but it is still decided according to your needs.

General regular hydraulic wrench brand in the production of quality management, it has been a strict quality testing of products to ensure that the products are qualified to enter the market, and they will use advanced testing equipment, but also need to pass the test of the national testing organizations to be able to, the user in the purchase, you can directly request the manufacturer to carry out torque testing.

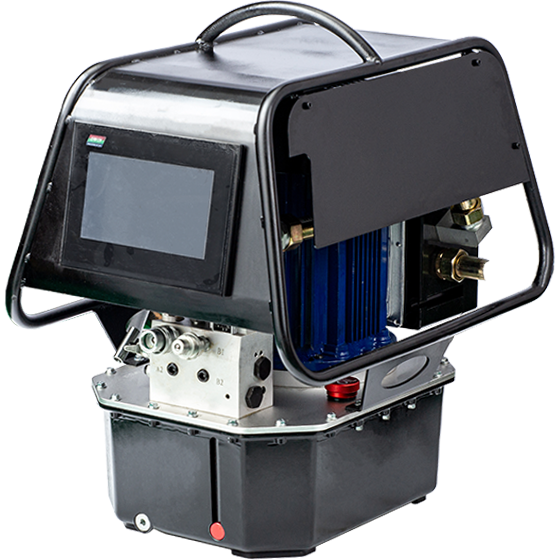

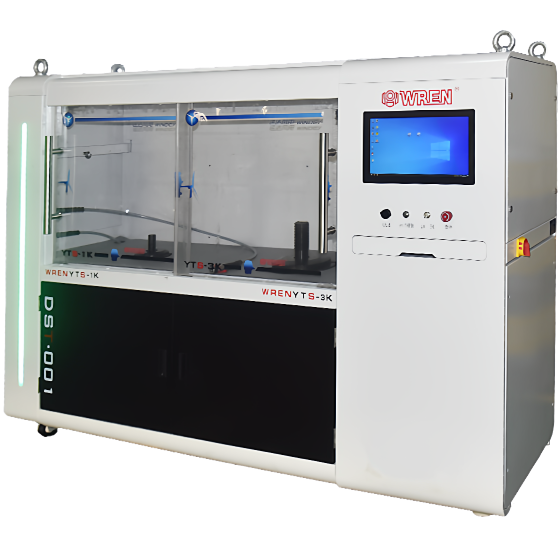

Hydraulic Wrench Test Bench

l Precise calibration of hydraulic wrench input pressure and output torque

l The system interface is clear and easy to operate, the test data is displayed in real time, and the calibration report is generated.

l Dual sensors, support 500Nm-5000Nm, 3000Nm-30000Nm hydraulic wrench test.

l Certified by a third party organization with CNAS qualification, the calibration is in accordance with CNAS standards.

l Accuracy is ±1%.

l The cabinet is made of plate gold and the table top is made of aluminum alloy, which is safe and reliable.

Hydraulic wrench calibration test can also be entrusted to a third-party professional testing organizations, relatively speaking, the credibility of third-party testing is higher, but the cost is also more expensive, after all, according to a single unit for the charge, and at present the domestic professional testing organizations are only a few, the cycle is still relatively long;

If the user needs long-term hydraulic wrench torque calibration, you can also buy hydraulic wrench calibration testing equipment for self-testing, in the long run, you can save a certain amount of cost, and the test cycle is short, the only thing you need to pay attention to is that in the purchase of hydraulic wrench testing equipment, take into account the professionalism of the instrument as well as the standardization of the operation.

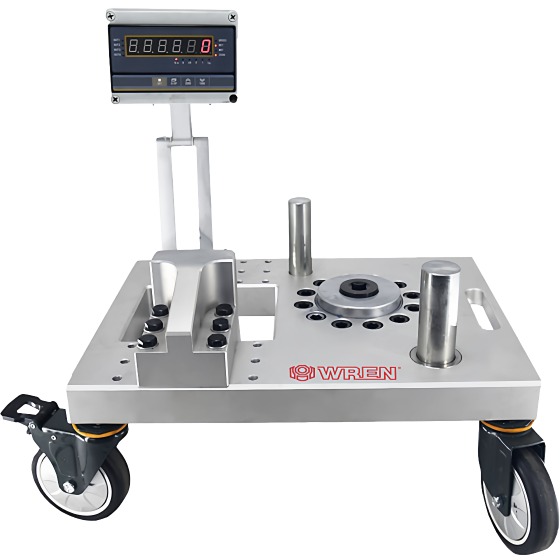

Hydraulic Wrench Torque Calibrator

l Accurate calibration of hydraulic wrench output torque

l Calibration results can be viewed in real time, record, output (support XLS, CSV, PDF format, support for Bluetooth connection to the tablet computer)

l Accurate testing, stable performance, feature-rich, easy to operate

l Can meet the 800Nm-20000Nm torque wrench test

l Sensor accuracy of ±0.5%

WREN engineers can provide a full range of pre-sale, in-sale and after-sale services. All WREN products are guaranteed to be free from defects in workmanship and materials, and as long as you own it, we will ensure that we will provide you with free repairs or replacements within one year after the product is sold.