-

Release Date:2026.01.12

-

Source:Hangzhou WREN Hydraulic Equipment Manufacturing Co., Ltd.

-

Page views:14

In oil drilling operations, the proper use of wrenches directly impacts equipment fastening quality, operational safety, and construction efficiency. Recently, Hangzhou WREN Hydraulic Equipment Manufacturing Co., Ltd. meticulously organized a specialized training session on operational precautions for electric torque wrenches for clients in the oil drilling industry. Combining theoretical instruction with hands-on practice, the training helped clients comprehensively master standard operating techniques for various wrenches, enhancing on-site operational safety and reliability.

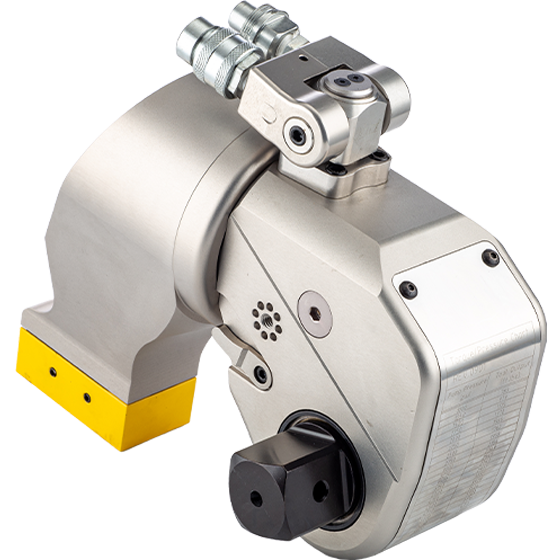

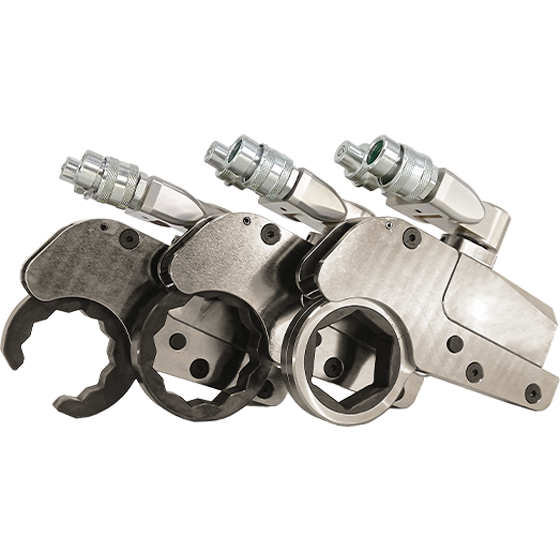

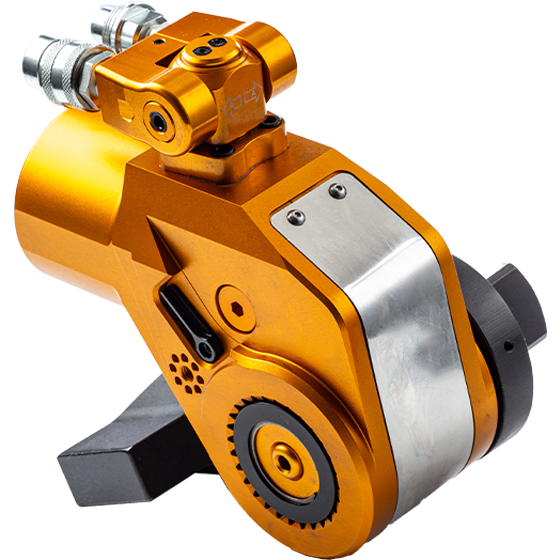

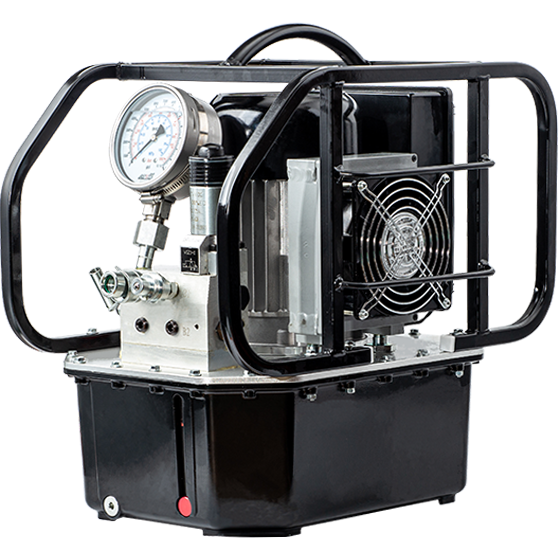

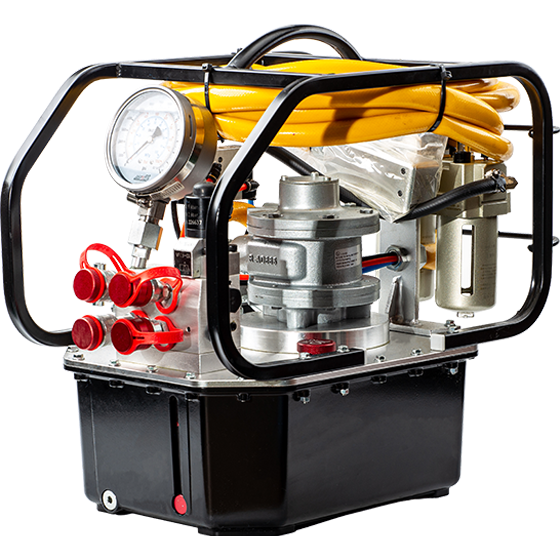

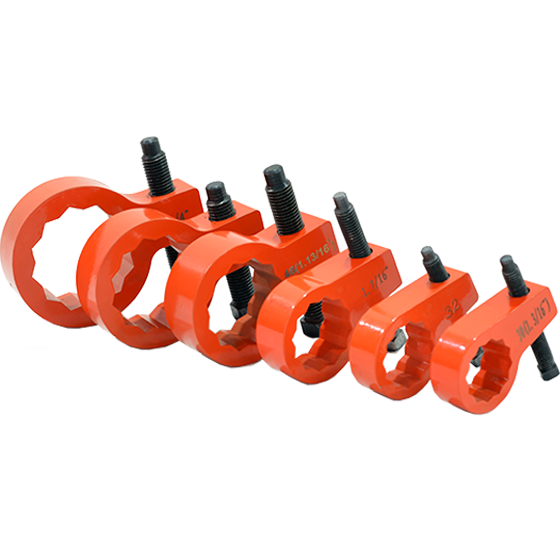

As an indispensable high-precision tool in oil drilling, electric torque wrenches are widely used in critical processes such as wellhead assembly, casing connections, and drill pipe tightening. However, due to complex operating environments and high technical demands, improper use may lead to tool damage, inadequate fastening, or even safety incidents. To address this, Hangzhou WREN Hydraulic organized this training to elevate client proficiency and ensure optimal equipment performance.

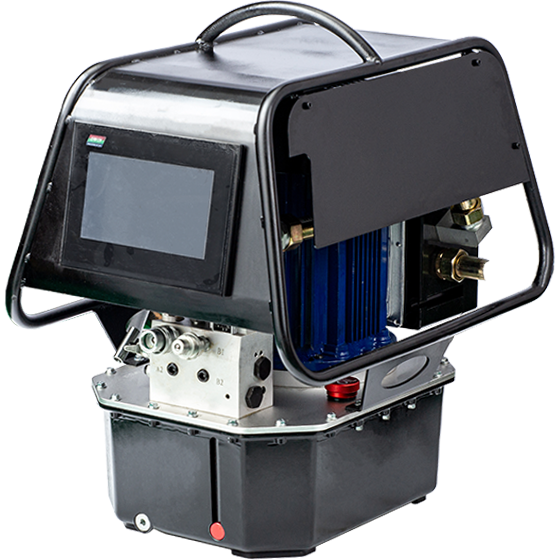

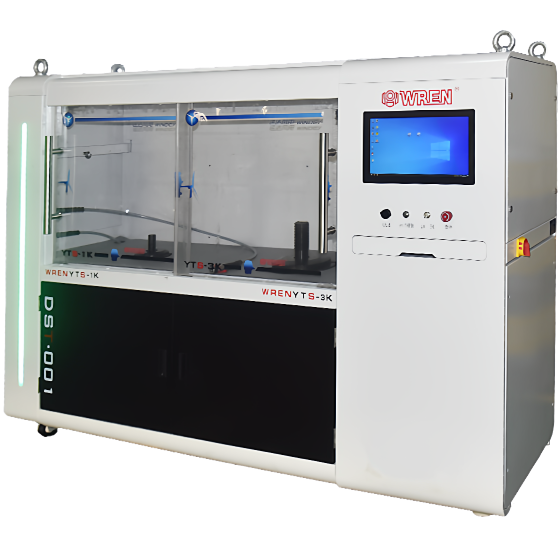

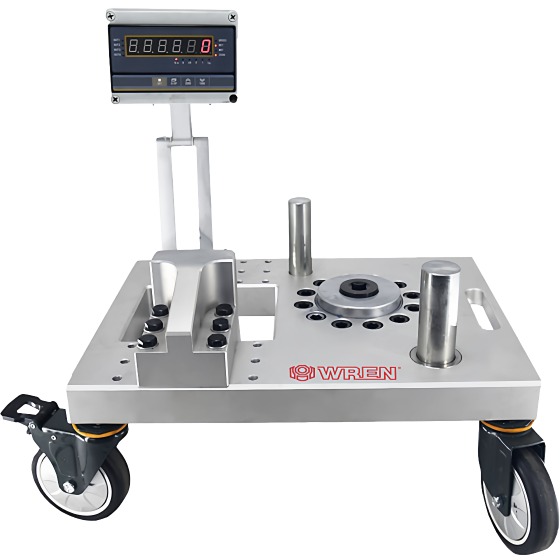

The training commenced with an overview of the electric torque wrench's fundamental structure and operating principles, enabling clients to gain a deep understanding of core component functions and interactions for more confident operation. Participants learned operational standards and precautions, proper installation and debugging procedures, torque setting and calibration, and more. Using real-world case studies, the training analyzed common issues such as torque deviation, motor overheating, and insufficient battery life during operation, providing corresponding solutions to help customers quickly address unexpected situations. Additional topics covered included troubleshooting common problems, daily maintenance and upkeep for extended product lifespan, and more.

To enable customers to grasp operational techniques intuitively, the training included hands-on practice sessions. Under engineer guidance, participants personally operated electric torque wrenches while simulating oil drilling field scenarios, ensuring each attendee could proficiently apply acquired knowledge.

As a specialized manufacturer in hydraulic tools, Hangzhou WREN Hydraulic will continue to empower oil drilling clients to maximize tool utilization efficiency through its integrated service model combining technical training, on-site guidance, and equipment optimization.