-

Release Date:2026.01.12

-

Source:Hangzhou WREN Hydraulic Equipment Manufacturing Co., Ltd.

-

Page views:14

Recently, Hangzhou WREN Hydraulic received a collaboration request from a renowned energy equipment manufacturer—to customize a synchronous tensioning device for solving the challenge of simultaneously tightening large clusters of bolts on heavy machinery. After multiple rounds of technical discussions and solution refinements, both parties finalized the partnership. The equipment has now been successfully deployed at the client's site, with WREN engineers on-site completing commissioning to enable efficient and precise bolt tightening operations.

Early in the collaboration, WREN's technical team engaged in deep discussions with the client, identifying their core pain points: Traditional single-bolt tightening methods often caused uneven force distribution across flange surfaces, increasing the risk of seal leakage. Additionally, the step-by-step operation of 18 bolts was time-consuming, severely impacting production efficiency.

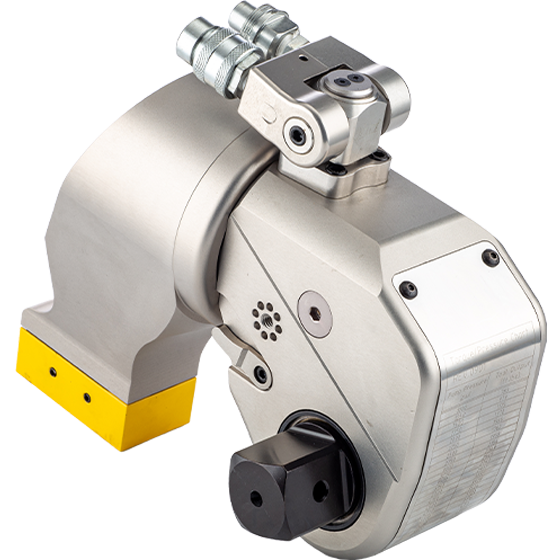

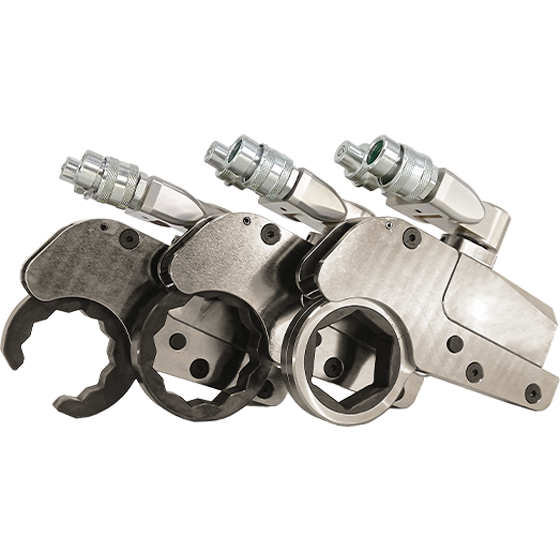

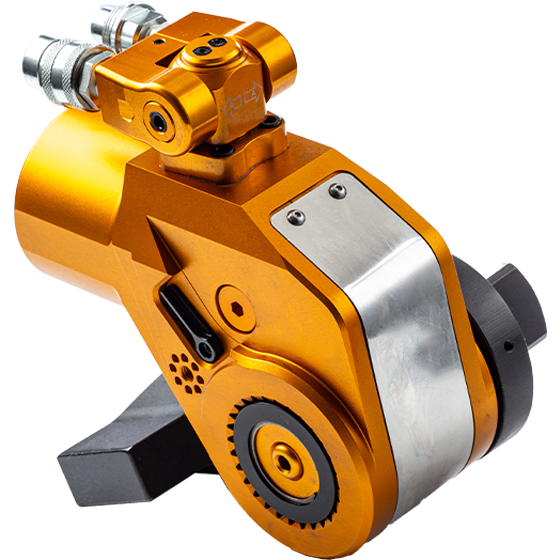

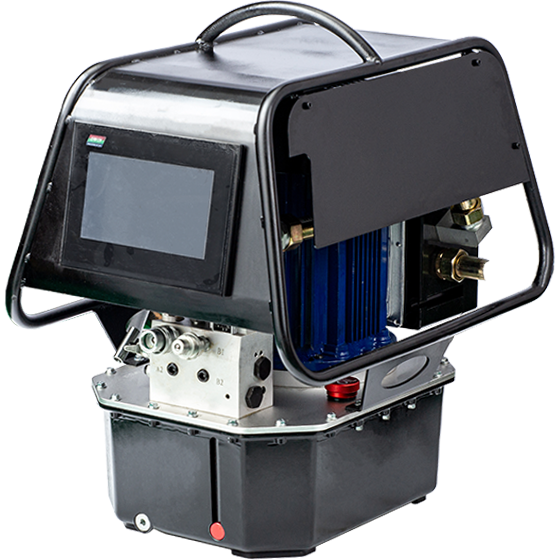

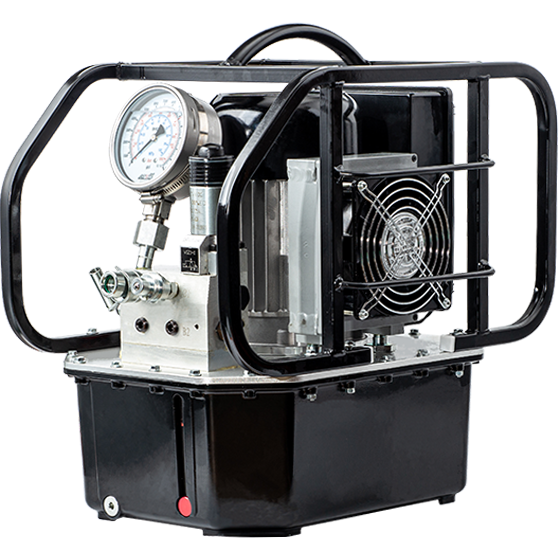

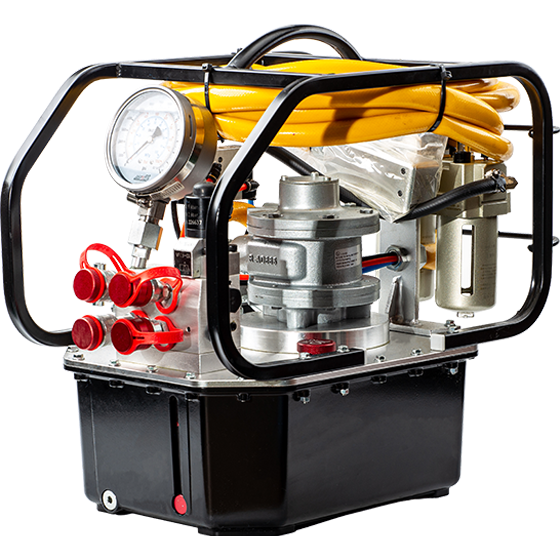

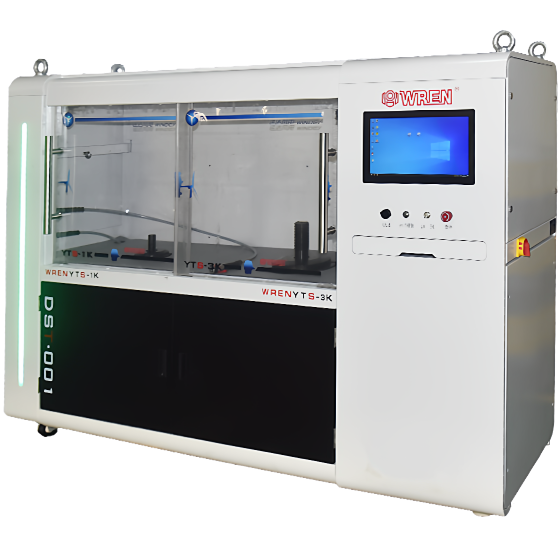

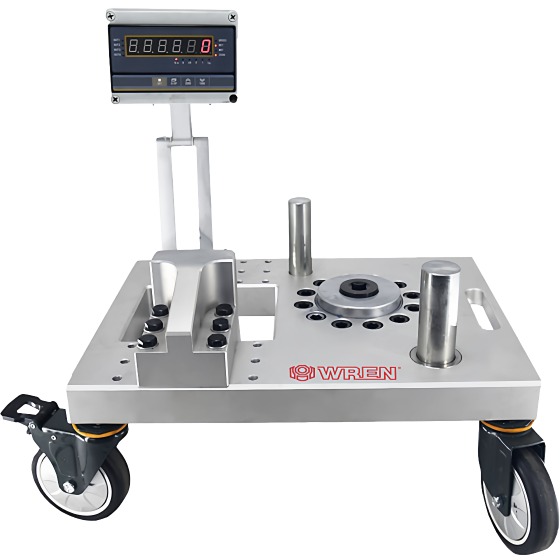

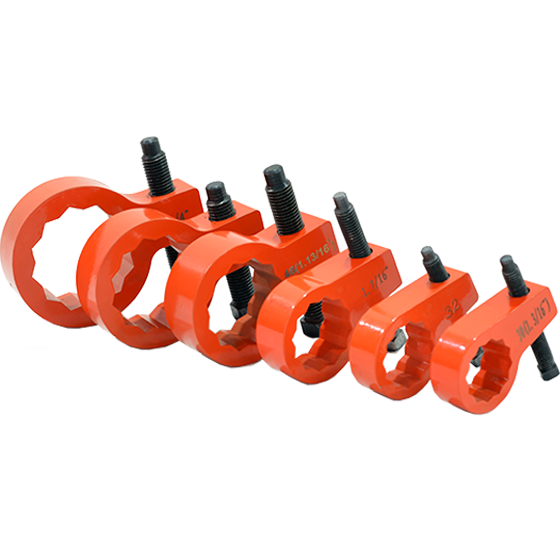

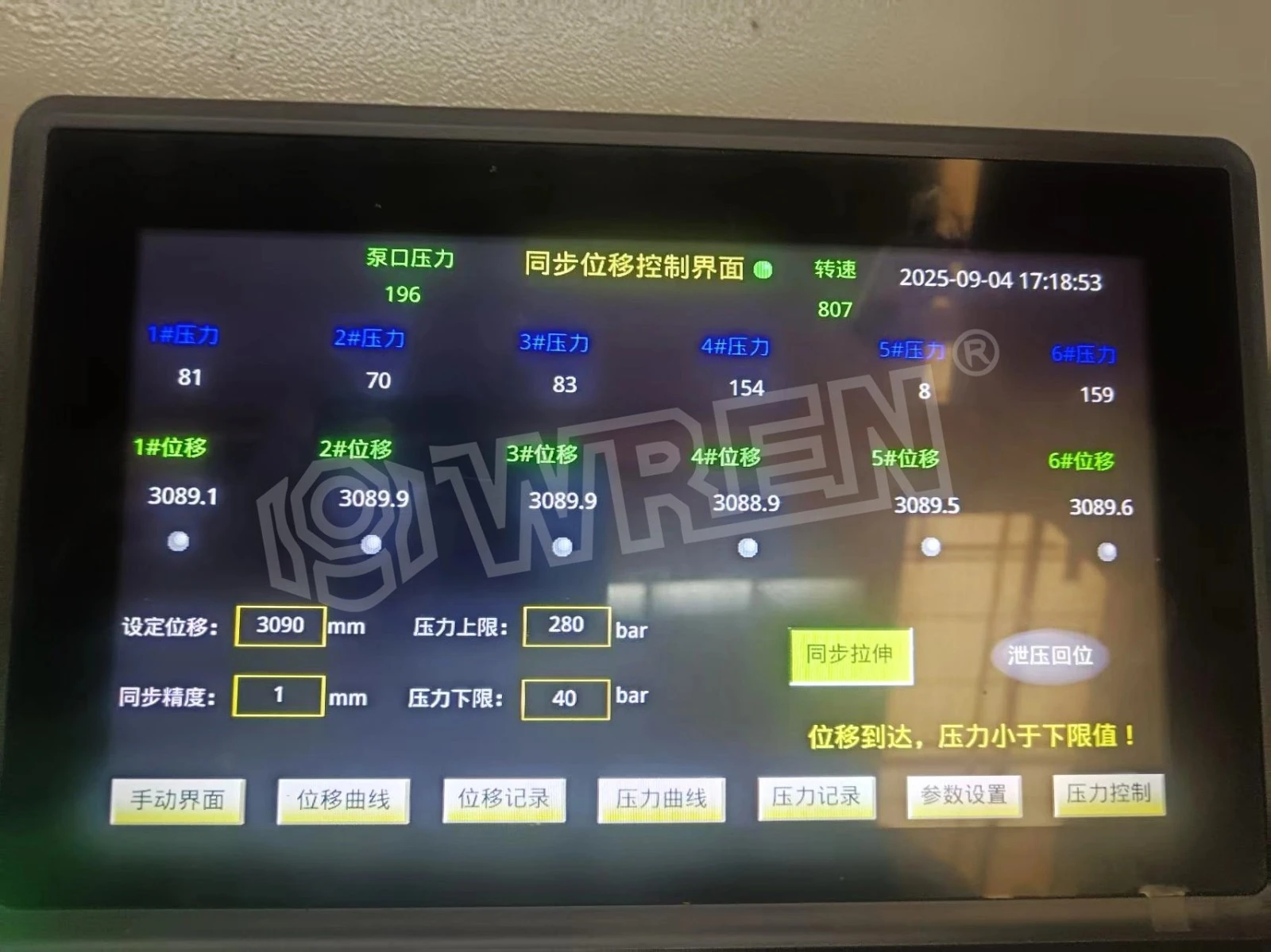

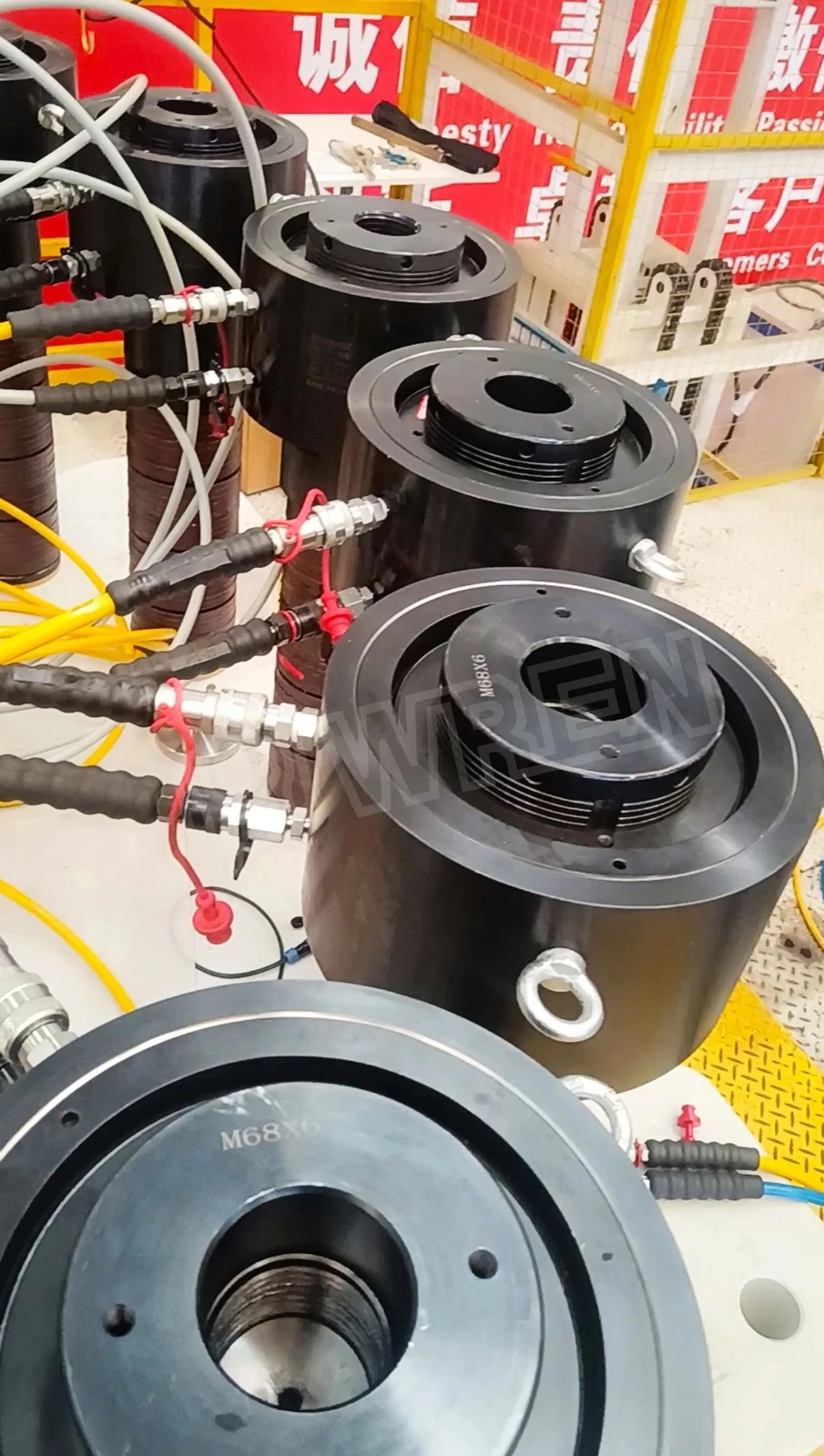

Addressing these requirements, WREN engineers customized a synchronous tensioning system tailored to the client's bolt specifications and flange dimensions. The complete system comprises one intelligent control cabinet, 18 hydraulic bolt tensioners, and supporting hydraulic hoses. The core advantage of this system lies in its ability to apply tension to all 18 bolts simultaneously, achieving “synchronized force application and tightening” to prevent flange deformation. Concurrently, all tension data—including force, pressure, and duration—is displayed in real-time on the control cabinet screen, enabling operators to monitor and record parameters. This fully meets the customer's requirements for “high precision, high efficiency, and traceability.”

After weeks of production and rigorous testing, each tensioner in this synchronous tensioning system passed multiple quality inspections, and the control cabinet's program operations underwent repeated debugging to ensure flawless functionality. The system ultimately met factory standards and was fully assembled for shipment to the customer's construction site.

Upon the equipment's arrival at the customer's site, the Hangzhou WREN technical service team immediately drove to the location to commence a two-day installation and commissioning process. Considering the large size of the equipment and the dense distribution of bolts, the engineers prepared a detailed on-site service plan in advance to ensure every step was efficient and orderly.

At the conclusion of the on-site service, the engineers also provided systematic training for the customer's operators. They explained and demonstrated everything from daily equipment maintenance to troubleshooting common faults, ensuring the customer could operate the synchronous tensioning device independently and safely.