-

Release Date:2026.01.12

-

Source:Hangzhou WREN Hydraulic Equipment Manufacturing Co., Ltd.

-

Page views:14

In August 2024, WREN engineers traveled to Beijing to provide on-site after-sales support for an energy company. Having collaborated with WREN for many years, this client entrusted us to design a lifting device for their transmission chain alignment project.

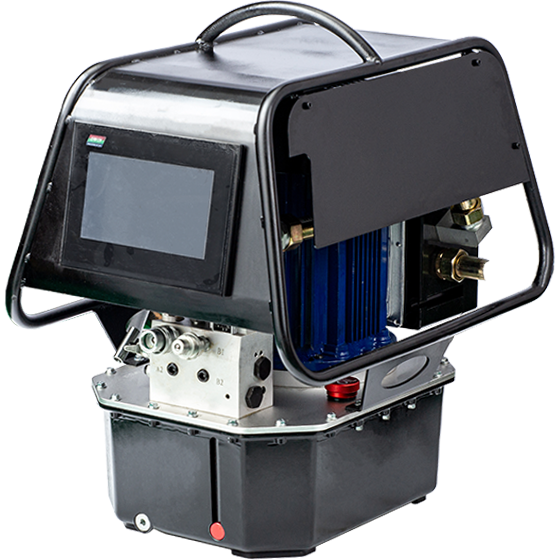

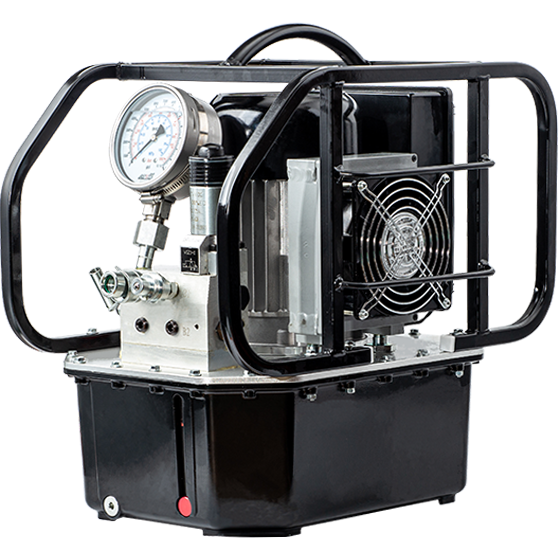

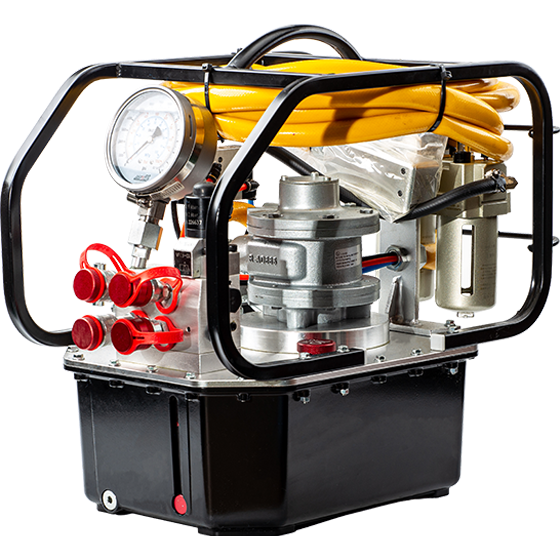

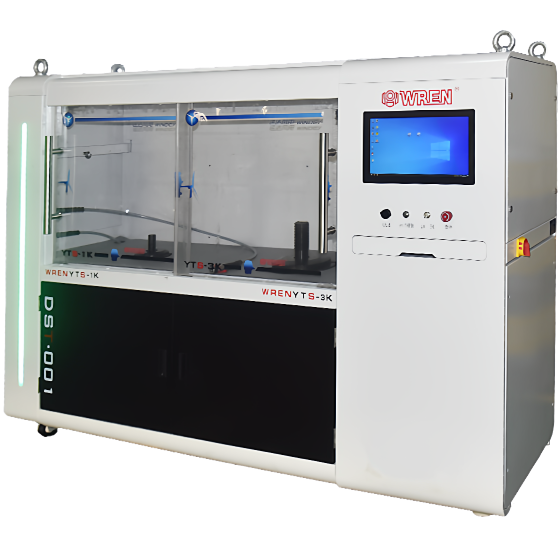

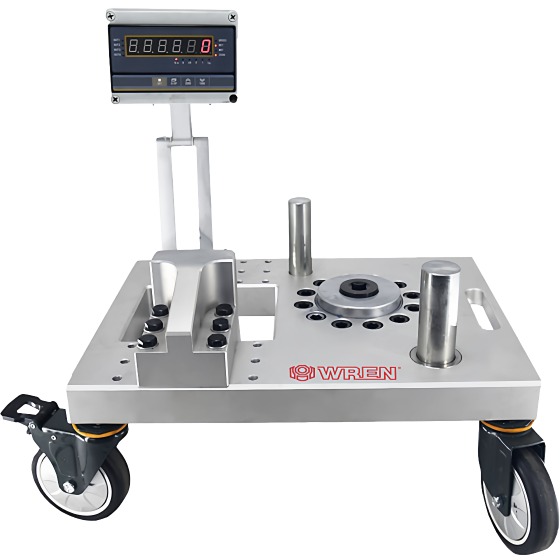

The synchronized hydraulic cylinder lifting system we designed represents an advanced hydraulic solution for precise load elevation and positional adjustment across multiple points. It primarily comprises a pump station, hydraulic cylinders, a control system, and essential sensors and valves. The pump station serves as the power source, hydraulic cylinders function as actuators, while the control system coordinates overall operations.

By adjusting the opening and closing frequency of solenoid valves, synchronized lifting is ensured even under multi-point load imbalances. The advanced system also incorporates variable frequency drives (VFDs) to continuously regulate oil pump flow by adjusting motor speed, thereby precisely controlling jack lifting speed and synchronization.

This device not only enables multi-point synchronous control but also prioritizes safety. It ensures loads remain securely supported during power outages or hydraulic failures, preventing accidental descent.

As a high-precision, high-safety load control technology, the hydraulic cylinder synchronous lifting device has played a vital role across multiple industries. Through continuous technological innovation and market expansion, the application prospects for such systems will grow even broader in the future.

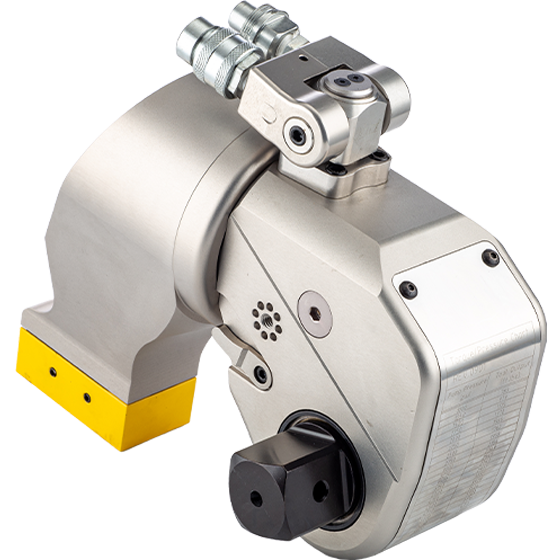

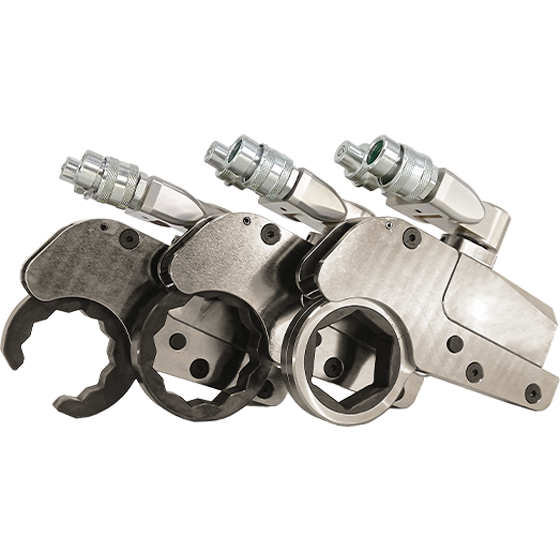

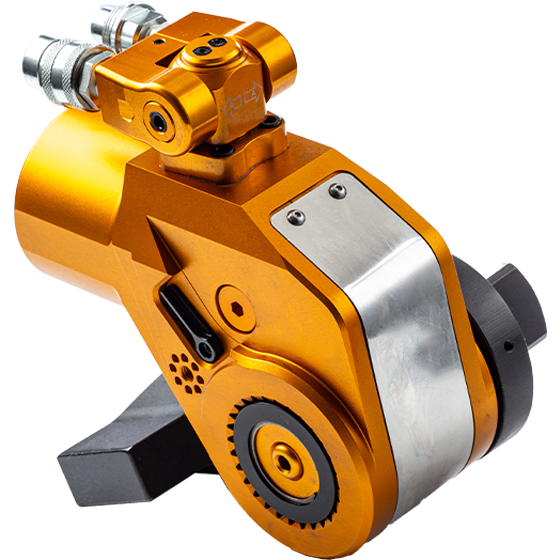

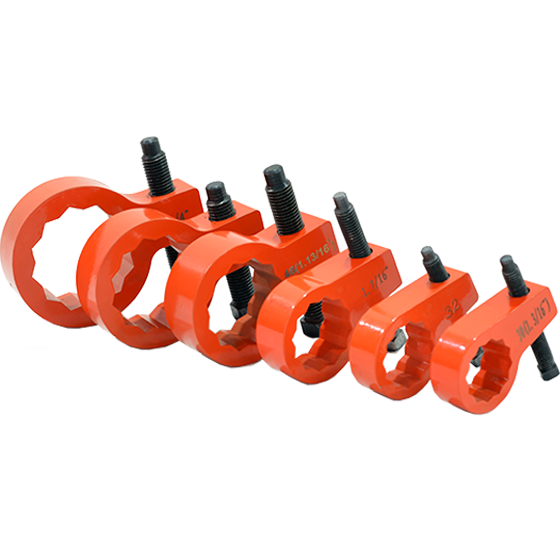

WREN engineers provide comprehensive pre-sales, sales, and after-sales support. All WREN products are guaranteed free from defects in workmanship and materials. For one year after purchase, we offer complimentary repair or replacement services. Our hydraulic wrench and bolting accessories range from common household types to specialized variants, covering all requirements.